What is Volumetric Efficiency (VE)?

VE is a ratio of actual engine breathing volume to displacement. For example, a 2.0L engine breathing only 1.5L of air (every two crankshaft revolutions) is breathing at a ratio of 1.5/2.0, or 75%. Low VE is a simple indicator of a whole category of breathing faults. Intake or exhaust restrictions, engine timing faults, and air measurement faults are all common causes of low VE.

Possible Cause Categories

While it may seem overly simplistic, every drivability fault and many P-codes are caused by one of the following:

- Air (whole-engine or single-bank breathing)

- Fuel (including fuel supply and the O2 sensor/Fuel Trim feedback loop)

- Ignition & cylinder contribution (including single-cylinder engine mechanical)

- In rare cases, drivetrain, suspension, or other external variables

You may be thinking of all of the tricky diagnostics you’ve been involved with, but they really can all be reduced to these 4 categories. Even if the actual diagnosis is something very specific, such as a clogged converter, breathing is affected. Therefore, a failed VE test puts a clogged converter on the possible cause list. In other words, all drivability faults are ‘measurable’ in one of the categories from the bullet list above. Therefore, proving which category contains your fault prevents testing in the other three categories, saving you time and focusing your diagnostic path.

Most may be found by testing the ignition system, graphing Fuel Trim PIDs, and performing a VE calculation. Fuel Trim and VE are very simple tests, so they are the best place to start, and as you’ll see, a few minutes of testing goes a long way toward narrowing down the list of more complicated tests to perform. Your only job in an initial diagnosis is to:

- Identify the potential general category of concern.

- Create a broad possible cause list.

- Make a list of easy tools and tests that may eliminate the most possible causes from the list with the least effort.

- Test the few possible causes that remain.

Volumetric Efficiency (VE) Test Setup

VE testing isn’t just ‘one more thing to check.’ Rather, it’s a high level indicator of an entire category of faults you may or may not need to check. It is often the best first test because it is very easy, and there are only two possible outcomes:

- The test passes, in which case you’ve just proven that you don’t need to check vacuum, whole-engine or single-bank compression, cam timing, or for intake or exhaust restrictions.

- The test fails, in which case you’ve proven that all of those possible causes are still on your list, and further testing is not a waste of time.

To perform a VE test, all you need is:

- A vehicle with a MAF sensor

- A VE calculator

- A Scan Tool displaying the following PIDs

- MAF in grams/second or pounds/minute

- RPM

- IAT (air temperature affects density)

- Barometric value (or check online for current atmospheric pressure)

Volumetric Efficiency (VE) Test Procedure

While graphing the PIDs, accelerate at wide-open-throttle (WOT) to near redline in first or second gear. Capture the movie or screen on the Scan Tool and return to the shop to enter the peak RPM and MAF values into the VE calculator along with intake air temperature, altitude, and engine displacement. The VE calculator will let you know the engine’s breathing efficiency.

Interpreting Test Results

The table below shows approximate ranges for the test. As you can see, sometimes the results aren’t clear because some engines are naturally more or less efficient. For example, a 2-valve pushrod V8 from GM doesn’t breathe very efficiently even when new, and 80% is a decent result. On the other hand, a 4-valve Hyundai with variable valve timing and intake tuning should get to 95%. Therefore an 80% result on a 5.3L Yukon V8 is a pass, but on a 2.4L Sonata it’s a fail.

The good news is that the results are often very obvious, so don’t worry about the ‘fuzzy’ result range unless you have to. Even then, you can often reason your way through a result. For example, if our hypothetical Sonata barely runs, our ‘failed’ 80% result does indicate a fault, but isn’t bad enough to explain the barely running engine. Look for something else. On the other hand, if the complaint is ‘it seems like it doesn’t have as much power’, the 80% result completely explains that symptom.

| VE | Interpretation |

|---|---|

| 90% or More | No breathing faults are present, or at least they are so minor that they will not cause a code to set or a customer to report a symptom. Note that non-turbo engines with very clever engine and intake designs may exceed 100%. |

| 76-89% | The ‘fuzzy’ zone. Consider the engine design (e.g. number of valves, number of cams, use of VVT, use of variable intake). Also consider whether the vehicle is designed for performance, economy, or workload when calibrating your expectations for this test. The higher the result in this range, the less obvious the symptom, so consider the severity of the fault you are diagnosing before jumping to conclusions. |

| 56-75% | This range clearly indicates a breathing problem. Use Fuel Trim to determine if this is a real breathing fault or just a sensed breathing fault. |

| 55% and less | Very few engines will even run if the actual breathing is under 55%. However, if it’s a ‘fake’ breathing fault, then Short Term & Long Term Fuel Trim may be able to add enough fuel (often over 50% combined) to keep the engine running. Therefore, if your results are in this range and the engine runs, verify high Fuel Trim and then diagnose this as a MAF or intake duct fault. |

Real vs. Fake Breathing Faults

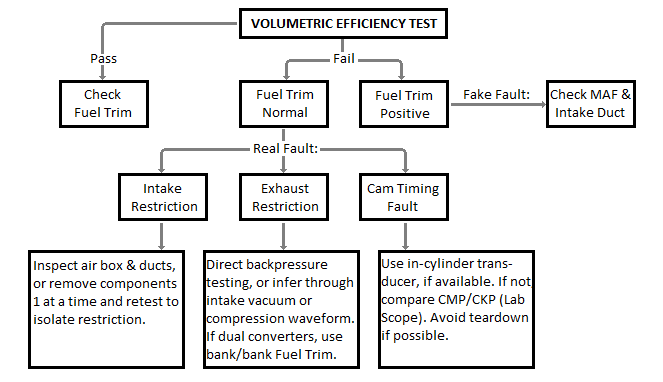

The chart below shows how to use test results as part of a larger diagnostic ideology. If the VE test passes, you didn’t waste your time. Rather, you eliminated a whole category of faults, preventing you from wasting time testing for faults that cannot be the root cause. Move on to Fuel Trim testing because it’s the next easiest fault category. If the VE test fails, you still need to check Fuel Trim because the comparison is a critical differentiator between actual breathing faults and sensed (or ‘fake’) breathing faults.

- A real breathing fault means that airflow is actually low. The MAF reports this low airflow, so the PCM applies a low fuel injector command as well. The result is a correct air/fuel ratio, and therefore, normal Fuel Trim values. Possible causes include:

- Restricted intake (including faulty variable induction)

- Restricted exhaust

- Incorrect camshaft timing (mechanical VVT control)

- Major engine mechanical issues

- A fake breathing fault means that the MAF reports lower than actual airflow. The PCM applies a low fuel injector command to correspond to low sensed airflow, so the actual air/fuel ration is too lean. This results in high Fuel Trim values. Possible causes include:

- A failed MAF sensor (including the MAF connector and related circuits)

- A contaminated MAF sensor

- Debris-based turbulence upstream of the MAF sensor

- A leak in the intake duct between the MAF sensor and throttle plate

Turbocharging & Supercharging

Many turbocharged and supercharged engine skip the MAF sensor in favor of a MAP-driven fuel management strategy (or ‘speed-density’). If you do have a MAF sensor, the results should be well over 100% because the whole point is to cram more air into the cylinder than it can hold at atmospheric pressure. For example, if a 2.0L turbocharged engine has a VE result of 150%, then it’s really breathing 3.0L of air. In fact, most modern small engines with turbocharging have VE results in the 170-185% range.

What is a ‘known-good’ range? Every engine is different, so our only advice is to throw in some instinct. If the system is rated at 8 PSI of boost, that’s just over half of atmospheric pressure. Once you throw in some intake and exhaust flow resistance, you’ll be in the 130-150% range. On the other hand, many modern engines use 15-20 PSI of boost (crazy, right?). The flow restrictions really stack up at that level, so passenger vehicle engines will rarely exceed the 170-185% range even though the absolute pressure can exceed 2 atmospheres.

For additional information and examples, we have integrated VE into many of our engine performance training manuals. If you don't have any of them, we recommend starting with Advanced Drivability Diagnostic Strategies.

Close